米兰体育(中国)

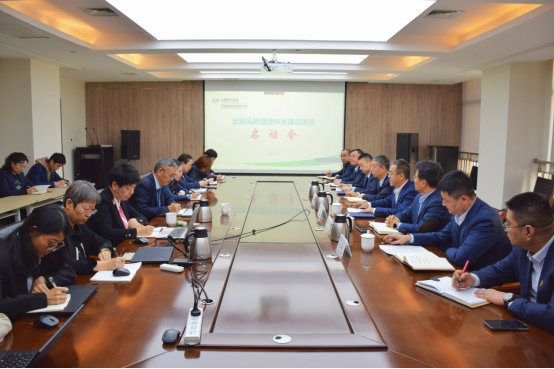

夯实高质量发展根基 打造全面风险管理体系:财务公司正式启动...

为健全公司全面风险管理体系,促进公司高质量发展,满足监管机构审慎监管的核心要求,2024年12月13日下午,“西电财司全面风险管理体系建设咨...

- 2024-12-12

- 2024-12-11

- 2024-10-11

- 2024-09-26

票据业务:029-84490405 结算业务:029-84244128 外汇业务:029-84251843

举报电话:029-84490402 举报邮箱:bgs@xdcwgs.com

公司地址:西安市高新区唐兴路7号C座6层/7层 邮政编码:710075

陕ICP备2021006134号 版权所有:米兰体育网页官网  陕公网安备 61019002001683号

陕公网安备 61019002001683号